- Product quality has passed ISO, GB/T, EN131, etc.

- Product style supports customized service.

- Provide 24-hour online technical support.

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

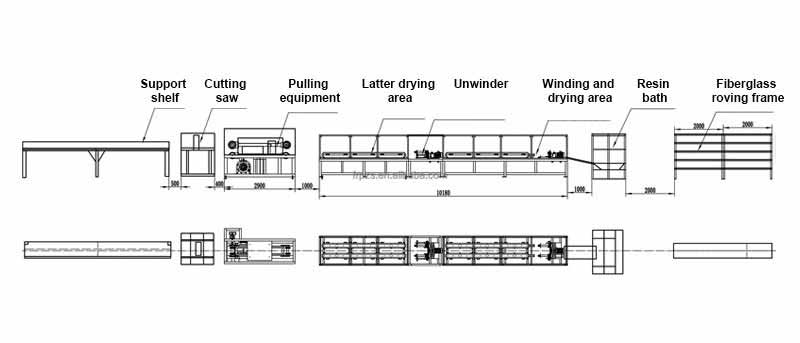

The FRP pultrusion winding production line is a special equipment for FRP stretching and winding. Its continuous production can significantly improve the production efficiency of pipes. Because glass fiber, felt, cloth and other reinforcing materials are evenly wound in the circumferential direction, the pressure resistance of the pipe is improved. Matched with pultrusion machinery, it can be used to produce various specifications of drawing and winding pipes with a diameter below φ210mm.

The FRP pultrusion winding production lineis mainly composed of yarn frame, dipping tank, winding, oven, tractor, cutting saw and stacking device.

1. Yarn frame: Place yarn group and adopt steel plate, steel pipe and Angle steel welding structure.

2. Dipping tank: Made of stainless steel welding, internal yarn pressing roller to make roving fully impregnated in resin.

3. Winding device: Gear drive line roller around the product, winding thread. Adopt frequency conversion speed regulation mode, speed stepless adjustment.

4. Unwinding device: Gear drive is adopted to push down the winding belt which is wound to the glass and steel bar to form the thread. Frequency conversion speed regulation is adopted to adjust the speed stepless.

5. Oven: Casting aluminum heater, intelligent temperature controller temperature control. The heating box adopts split structure,

which can be convenient Remove dripping resin and fill the interior with thermal insulation.

6. Automatic tracking cutting saw: According to the specific requirements of the production line of glass and steel line fixed length cutting.

7. Product stacking device: FRP REBAR after cutting stacking, by the production personnel to take away

|

Technical parameters |

|

operating voltage |

380V & 440V /50HZ |

Air pressure |

0.4-0.6Mpa |

|

total power |

40Kw |

center height |

1000mm |

|

Winding Numbers |

2 |

Center distance of winding head |

411mm |

|

Winding speed |

9-95rpm |

Coil diameter |

Max 40mm |

|

Traction speed |

0.1-1m/min |

The traction |

Max100Kn |

|

Effective track holding length |

2500mm |

Track clamp width |

600mm |

|

Cutting range |

(W X H)600X65mm |

Cuttin speed |

2850rpm |

|

Tracking cut stroke |

700mm |

Fixed-length |

travel switch |

|

Unit dimensions |

20000X1850X1450mm |

|

FRP pultrusion winding production line layout

FRP pultrusion winding production line details display

Fiberglass shelf

Fiberglass impregnation

Fiberglass Rebar Winding Equipment

Fiberglass Rebar Drying Equipment

Fiberglass Rebar Pulling Equipment

Control box of glass fiber reinforced steel winding equipment

Hot Tags: frp pultrusion winding production line, China, manufacturers, factory, price, Fiebrglass platfrom ladder, pig flooring, fiberglass marine pilings, frp barrier, Fiberglass Grating Fence, composite sheet pile