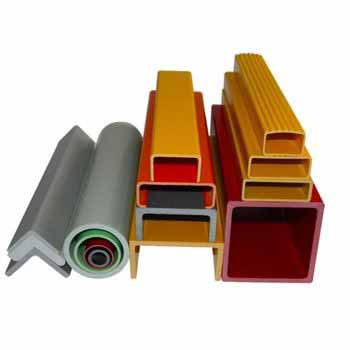

What are the characteristics of Frp composite materials? What are its advantages and disadvantages? Frp is a manufacturing material with faster production speed and is widely used in our daily life. Frp has a unique appearance, cost-effective material, and is durable. As a high-quality manufacturing material, it is also widely used in other industries.

Advantages of Frp composite materials

1. Bright, high wear resistance, only 1.5~2. Only 1/4~1/5 of carbon steel, but the tensile strength is close to or even exceeds that of carbon steel, which can be compared with excellent carbon steel.

2. Good corrosion resistance, good corrosion resistance, strong immunity to gas, water, acid, alkali, salt, and various oils and organic solutions.

3. The production process can be applied according to the product appearance, standards and the number of soft molding processes; the production process is simple, it can be plastic products, and the economic benefits are outstanding, especially the appearance is complex, it is not easy to produce a small number of products, and the technology and sense of honor are more prominent.

4. Appearance design patent scheme design with high quality, rich material selection, realize product performance, flexible scheme design, various structural products and product requirements, so that the product is intact.

Disadvantages of Frp composite materials

1. Aging phenomenon is a common defect of plastics, except for glass fiber reinforced plastics, which can easily cause performance melting in the aspects of ultraviolet rays, sand wind, rain and snow, chemical substance analysis, mechanical stress, etc.

2. The long-term temperature difference of general Frp can be used at high temperature for a long time. Generally, the tensile strength of polyester FRP is significantly reduced at 50°C, and it is generally only used at 100°C; the tensile strength of general epoxy resin glued FRP exceeds 60°C, and the tensile strength is significantly reduced. However, continuous high-temperature resistant epoxy resin glue can be selected to make the long-term working temperature 200~300°C.

3. The ductility of abrasives is low. The ductility of Frp composite materials is twice that of logs, but 10 times that of steel (E=2.1*106), so it is generally difficult to deform in the product structure. It can also be made of biomimetic architectural and decorative partition structures, or consist of high modulus fiber or lifting ribs.