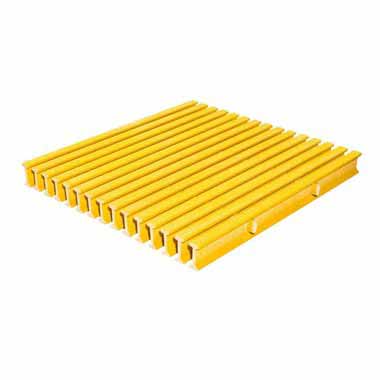

Pultruded fiberglass rods are a type of composite material that is made by pulling fibers of glass through a resin bath and then through a series of dies. The resulting product is a rod that is strong, lightweight, and corrosion-resistant, making it ideal for a wide range of applications. In this essay, we will explore some of the benefits and uses of pultruded fiberglass rods.

Pultruded Fiberglass Rods

Benefits of Pultruded Fiberglass Rods:

High strength-to-weight ratio: Fiberglass is a strong material on its own, but it becomes even stronger when it is combined with resin and pultruded into rods. In fact, pultruded fiberglass rods are often used as a replacement for steel in applications where strength and stiffness are required but weight is an issue. This makes it ideal for use in construction, transportation, and other industries where weight is a critical factor.

Corrosion Resistance: Fiberglass is resistant to many chemicals, making pultruded fiberglass rods an ideal material for use in harsh environments. This makes it suitable for marine and offshore applications, as well as chemical process plants and other industrial environments.

It is an excellent thermal and electrical insulator and has a low coefficient of expansion, meaning it resists thermal expansion and contraction. It is also resistant to UV radiation, making it suitable for outdoor applications.

There are many different uses for pultruded fiberglass rods, depending on the specific properties and characteristics of the material. Some common applications include:

Structural support: Pultruded fiberglass rod is often used as a structural support in construction and other applications where strength and rigidity are required. It is especially useful in bridge construction, where its low weight and corrosion resistance make it an ideal choice.

Transmission poles: Pultruded fiberglass rod is often used in the construction of transmission poles, due to their strength and durability. It is also resistant to electrical current, making it a safe choice for use in high-voltage transmission lines.

Antenna masts: Pultruded fiberglass rod is used in the construction of antenna masts, due to their low weight and corrosion resistance. It is also a good insulator, which helps to protect the electronic equipment housed within the mast.

Marine applications: Pultruded fiberglass rod is often used in marine applications, due to their corrosion resistance and low weight. It is used in the construction of boats, docks, and other marine structures, as well as in the production of fishing rods and other marine equipment.

Chemical processing: Pultruded fiberglass rod is resistant to a wide range of chemicals, making it an ideal material for use in chemical processing plants and other industrial settings. It is used in the construction of chemical storage tanks and piping, as well as in the production of chemical processing equipment.

Overall, pultruded fiberglass rod is a versatile and useful material that has a wide range of applications. Its strength, corrosion resistance, and other useful properties make it an ideal choice for use in construction, transportation, marine, and industrial applications.