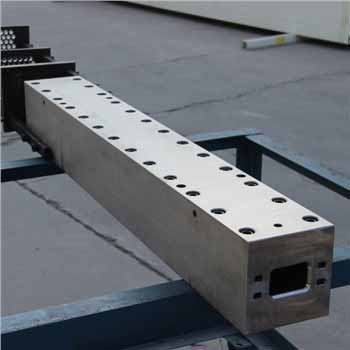

FRP Baffle Wall, also known as the Fiberglass Reinforced Plastic baffle wall, is a cost-effective, lightweight and corrosion-resistant solution for industrial water and wastewater systems, reservoirs, and municipal engineering projects. Made of composite materials, this baffle wall offers exceptional strength, stability and durability under harsh environmental conditions.

Key Features:

- Corrosion and rot-resistant: FRP Baffle Wall is immune to corrosion and rot, making it an ideal choice for applications in corrosive environments or where long-lasting durability is essential.

- Low conductivity: FRP has low conductivity, which makes it ideal for applications in high or low-temperature environments.

- Lightweight: FRP Baffle Wall is significantly lighter than traditional materials and can save installation, transportation and handling costs.

- UV stable: The product is designed to withstand exposure to UV radiation, making it an excellent choice for outdoor applications.

- Dimensionally stable: FRP Baffle Wall is designed to maintain its size and shape regardless of environmental conditions.

Other Related Keywords:

- Fiberglass baffle wall

- Composite baffle wall

- Water treatment baffle wall

Product Applications:

FRP Baffle Wall is ideal for industrial, municipal, and water treatment applications, such as:

- Water and wastewater systems

- Industrial tanks and chambers

- Municipal engineering projects

- Reservoirs and ponds

Conclusion:

FRP Baffle Wall is a superior alternative to traditional materials, offering exceptional strength, stability, and durability under harsh environmental conditions. Its lightweight, corrosion-resistant, dimensionally stable, and UV-stable properties make it a cost-effective and practical choice for various applications in industrial, municipal, and water treatment sectors.