1. Good corrosion resistance. Since the main raw materials of FRP are composed of polymer unsaturated polyester resin and glass fiber, it can effectively resist the corrosion of acid, alkali, salt and other media, as well as untreated domestic sewage, corrosive soil, chemical wastewater and many chemical liquids. In general, the corrosion of the pipeline can maintain the safe operation of the pipeline for a long time.

2. Good anti-aging performance and heat resistance performance. The glass steel pipe can be used for a long time in the temperature range of -40℃~70℃, and the high temperature resistant resin with special formula can also work normally at temperatures above 200℃. For pipelines that have been used in the open air for a long time, ultraviolet absorbers are added to the outer surface to eliminate ultraviolet radiation to the pipeline and delay the aging of FRP pipelines.

3. Good frost resistance. Below minus 20°C, the tube will not freeze and crack after freezing.

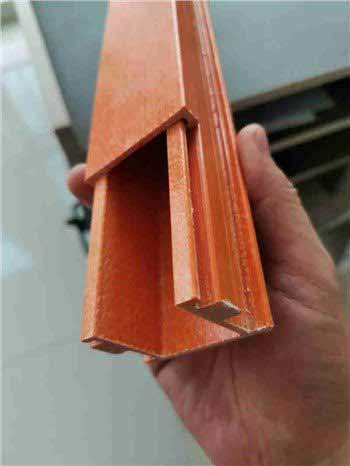

4. Light weight, high strength and convenient transportation. FRP pipes are not only light weight, high strength, strong plasticity, convenient transportation and installation, but also easy to install various branch pipes, and the installation technology is simple.

5. Good hydraulic conditions. Smooth inner wall, strong conveying capacity, no scaling, no rust, and low water resistance.

6. Good designability. FRP pipes can be designed and manufactured into pipes with different pressure levels and stiffness levels according to various specific requirements of users, such as different flow rates, different pressures, different buried depths and load conditions.

7. Low maintenance cost. Due to the above-mentioned corrosion resistance, wear resistance, frost resistance and antifouling properties of glass steel pipes, the project does not require measures and maintenance such as rust prevention, antifouling, insulation, and heat preservation. There is no need for cathodic protection for buried pipes, which can save engineering maintenance costs by more than 70%.

8. Good wear resistance. Put water containing a large amount of mud and sand into the pipe to conduct a comparative test on the effects of rotating abrasion. After 3 million rotations, the wear depth of the inner wall of the inspection tube is as follows: the steel pipe coated with tar and enamel is 0.53mm, the steel pipe coated with epoxy resin and tar is 0.52mm, and the steel pipe with surface hardening treatment is glass steel pipe It is 0.21mm. As a result, FRP has good wear resistance.

9. Good electrical and thermal insulation. FRP is a non-conductor, and the electrical insulation of the pipeline is excellent. The insulation resistance is 1012~1015Ω.cm. It is most suitable for use in power transmission, telecommunications line dense areas and mine areas. The heat transfer coefficient of FRP is very small, only 0.23, which is 1000 Fifthly, the pipeline has excellent thermal insulation performance.

10. Low friction resistance and high conveying capacity. The inner wall of the glass steel pipe is very smooth, with low roughness and frictional resistance. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and the value of cast iron pipe is 0.013. Therefore, FRP pipe can significantly reduce the fluid pressure loss along the way and improve the conveying capacity. Therefore, it can bring significant economic benefits: when the transportation capacity is the same, the project can choose the glass fiber reinforced plastic pipe with a smaller inner diameter, thereby reducing the one-time engineering investment; using the same inner diameter pipe, the glass fiber reinforced plastic pipe can reduce the head loss compared with other material pipes , Save pumping costs. In addition, FRP pipes can shorten pumping time and reduce long-term operating costs