What is GRP Pipe?

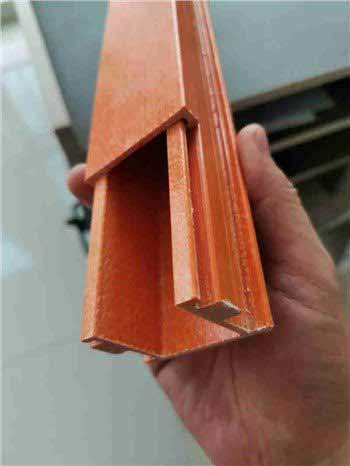

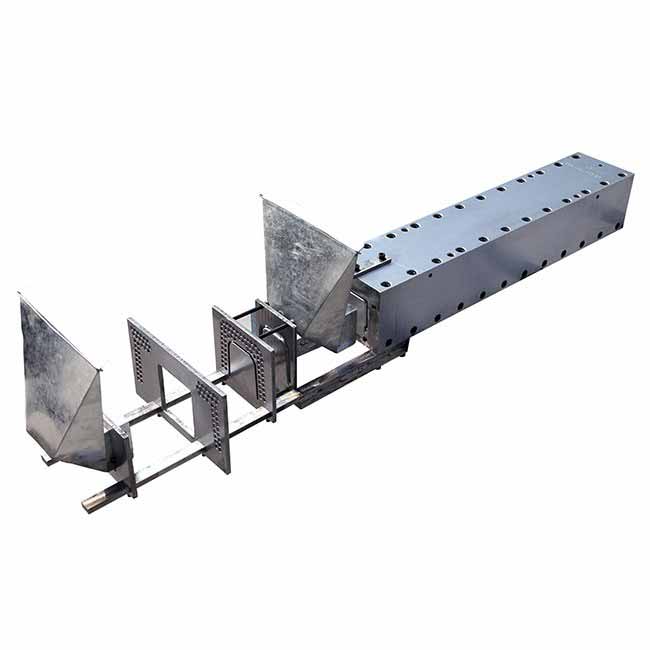

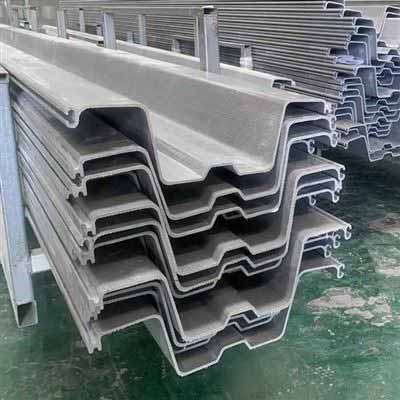

GRP stands for glass reinforced plastic, also known as fiberglass reinforced plastic (FRP) or glass fiber reinforced polymer (GFRP). It is a composite material made of a polymer matrix reinforced with glass fibers. GRP pipe is a type of GRP product that is shaped into cylindrical tubes or pipes for various applications.

What are the Advantages of GRP Pipe?

GRP pipe has many advantages over traditional materials such as steel, concrete, or plastic. Some of the main benefits are:

Corrosion resistance: GRP pipe can withstand harsh environments and resist corrosion from chemicals, seawater, soil, or bacteria. This reduces maintenance costs and extends the service life of the pipe.

Lightweight: GRP pipe is much lighter than steel or concrete pipe, which makes it easier to transport, install, and handle. This also reduces the need for heavy equipment and supports, and lowers the fuel consumption and carbon footprint of the project.

High strength: GRP pipe has high tensile and flexural strength, which enables it to withstand high pressures and loads. It also has good impact resistance and can absorb shocks and vibrations without cracking or breaking.

Thermal insulation: GRP pipe has low thermal conductivity, which means it can maintain a stable temperature and prevent heat loss or gain. This improves the energy efficiency and performance of the system.

Smooth surface: GRP pipe has a smooth inner surface, which reduces friction and pressure loss. This enhances the flow capacity and reduces the pumping costs of the system.

Design flexibility: GRP pipe can be customized to fit different diameters, lengths, shapes, colors, and fittings. It can also be easily joined by various methods such as adhesive bonding, mechanical coupling, or thermal fusion.

What are the Applications of GRP Pipe?

GRP pipe can be used for a wide range of applications in various industries such as:

Water supply and distribution: GRP pipe can be used to transport potable water, irrigation water, wastewater, stormwater, or seawater. It can also be used for hydropower generation, desalination plants, or water treatment plants.

Oil and gas: GRP pipe can be used to convey oil, gas, or petrochemical products. It can also be used for offshore platforms, pipelines, refineries, or storage tanks.

Chemical and industrial: GRP pipe can be used to handle corrosive fluids, acids, alkalis, solvents, or gases. It can also be used for cooling systems, fire protection systems, or ventilation systems.

Mining and metallurgy: GRP pipe can be used to transport slurry, tailings, ore, or minerals. It can also be used for leaching plants, heap leaching pads, or electrowinning plants.

Power generation: GRP pipe can be used to carry steam, water, or coolant for thermal power plants, nuclear power plants, or renewable energy plants.

Marine and civil engineering: GRP pipe can be used for seawalls, jetties, piers, bridges, tunnels, or culverts. It can also be used for floating structures, pontoons, or buoys.

Conclusion

GRP pipe is a versatile and durable solution that can meet the needs of various industries. It offers many advantages over traditional materials such as corrosion resistance, lightweight, high strength, thermal insulation, smooth surface, and design flexibility. It can be used for a wide range of applications such as water supply and distribution, oil and gas, chemical and industrial, mining and metallurgy, power generation, and marine and civil engineering.