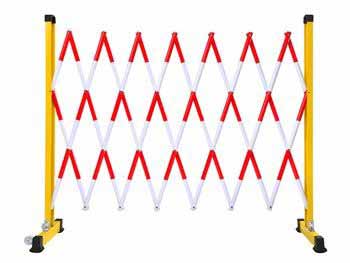

It has excellent acid resistance, alkali resistance, organic solvent resistance, salt resistance and many other gas and liquid corrosion properties, and it has incomparable superiority in the field of anti-corrosion. According to the requirements of actual use occasions, o-phthalic, isophthalic, and vinyl resins can be economically selected as the matrix material.

Because it is a composite of resin and glass fiber, its density is less than 2 kilograms per cubic decimeter, which is only 1/4 of steel and 2/3 of aluminum. Its strength is 10 times that of rigid PVC, and its absolute strength exceeds that of aluminum and ordinary steel. Its light weight can greatly reduce the foundation support, thereby reducing the material cost of the project. Its cutting and installation are simple, without hot and large lifting equipment, only a small amount of labor and electric tools, so that the installation cost is also greatly reduced.

The flame propagation rate of ordinary flame-retardant grille (ASTM E-84) does not exceed 25; the flame propagation rate of advanced flame-retardant vinyl grille does not exceed 10. The oxygen index is not less than 28 (GB 8924).

It has excellent electrical insulation, no breakdown under 10KV voltage; no electromagnetic properties, and can be used on magnetically sensitive equipment; the special structure of the glass fiber reinforced plastic grille also has the characteristics of anti-slip and anti-fatigue.

The color can be selected arbitrarily. Color can be customized according to customer requirements to improve the environment of the production site. Generally, the colors of FRP gratings are: yellow, black, gray, green, blue, red, and transparent or translucent. During use, one color can be used alone or in combination.