- Product quality has passed ISO, GB/T, EN131, etc.

- Product style supports customized service.

- Provide 24-hour online technical support.

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

Anticorrosive FRP plate grating Trench Cover

Grating is a moulded ,one-piece fiberglass reinforced plastic grating ,available in standard panels or custom panels made to order from drawings supplied. It is principally used for floors, platforms, stair tread, catwalks and trench covers.

Product Parameters

| Product Name | Fiber Reinforced Plastic Qrating Cover Plate |

Basic Raw Materials | Alkali free glass fiber + resin + filling powder |

Product Features | Light weight, high strength, convenient instalfation, high strength, designability, etc |

Scope Of Application | Sewage treatment plant walkway, cable trench, chemical plant, municipal, offshore platform, etc |

Grid Specification | 25/30/38/50mm |

Color | Reqular yellow, green, gray, black red and blue can be customized according to the color card |

RESIN SYSTEM:

| Resin Type | Resin Base | Description | Corrosion Resistance | Application |

OCR | Ortho | Moderate Corrosion Resistance | Moderate | No fire resistant requirement |

OFR-25 | Ortho | Moderate correction resistance and Fire retardant | Moderate | general performance in Acid ,Alkali resistant environment |

IFR-25 | ISO | Industrial Grade Corrosion Resistance and Fire Retardant | very good | good performance in Acid, Alkali resistant environment |

IFGR30 | ISO | Food grade corrosion resistance and fire retardant | very good | Meat product plant and food processing factory |

VEFR-10 | VINYL Ester | Industrial Grade Corrosion Resistance and Extra Fire Retardant | very good | High above normal performance in Acid ,Alkali resistant environment |

VEFR-25 | VINYL Ester | Superior Corrosion Resistance and Fire Retardant | excellent | superior performance in Acid ,Alkali resistant environment |

MP-5 | Phenolic Resin | Low smoke and superior fire resistance | excellent | highest requirement in cid ,Alkali resistant environment |

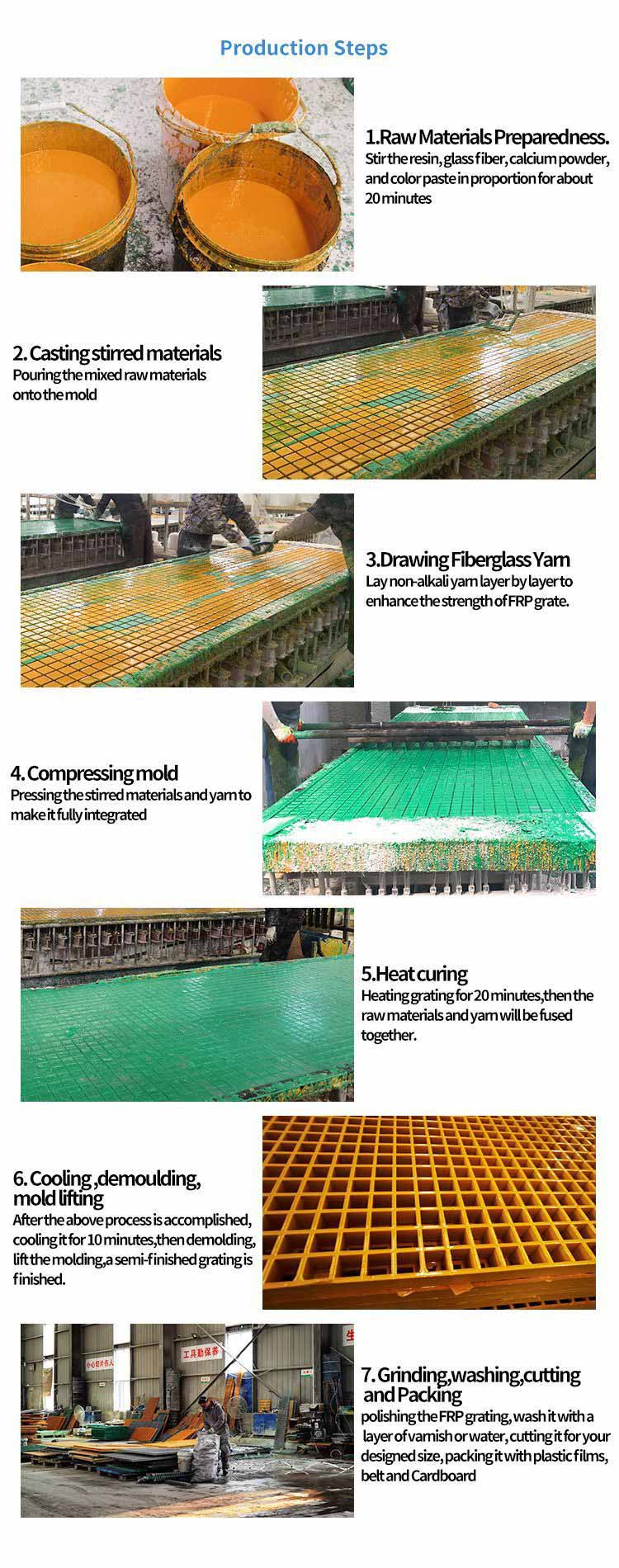

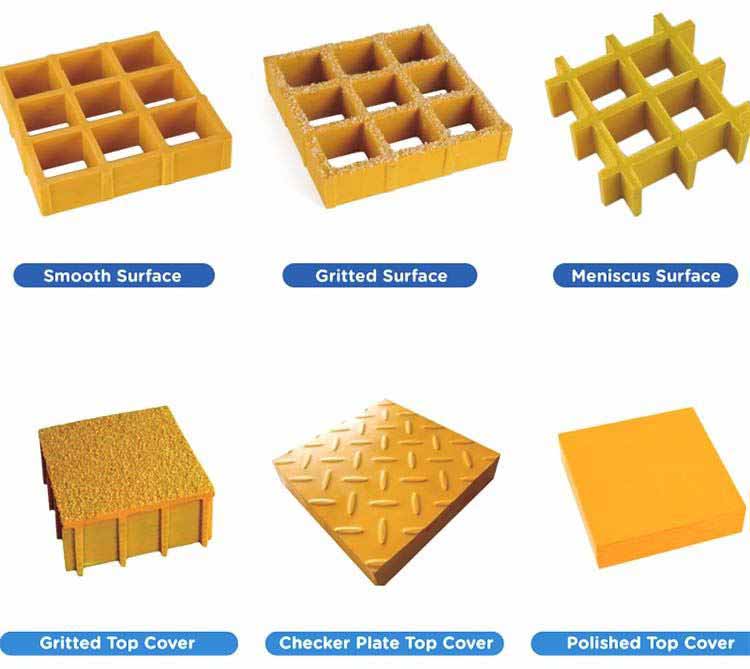

Different Types of Surface

The ordinary types

A: concave(formed naturally):anti-slip

B: Gritted: extraordinary anti-slip

C: Smooth:non-slip, generally used in some place that need decoration or other purposes.

Covered type

It is used in places where there is no hole, no liquid leakage, gas play or special requirement for hole.

A: Smooth covered grating :non-slip, easy dedusting.

B: Gritted covered grating: best perform at anti slip property

C: Pattern covered grating :it has a more artistic appeal but not very do a good job at anti slip function.

Advantages of FRP Gratings:

1. Smooth and beautiful appearance.

2. Corrosion resistance, never rust, long service life, maintenance-free.

3. Flame retardant.

4. Insulated, non-magnetic.

5. Light weight but high strength.

6. Strong designability, easy to cut, install and flexible in size.

7. Various colors are available, improve the use environment.

8. With slight elasticity, it can reduce workers' fatigue, enhance comfort and improve work efficiency.

Standard size of FRP Grating

| Thickness | Mesh size | Panel size | Open area | Weight |

(MM) | (MM) | (MM) | % | (kg/m2) |

25 | 38*38 | 1220*3660 | 68 | 12.5 |

1220*4076 | ||||

1220*4000 | ||||

30 | 38*38 | 1220*3660 | 68 | 14.75 |

1220*4000 | ||||

38 | 38*38 | 1007*4047 | 68 | 19.5 |

1220*3660 | ||||

1220*4000 | ||||

50.7 | 50.7*50.7 | 1220*3660 | 71 | 23.5 |

1220*4000 | ||||

30 | 19*19 | 1007*4007 | 40 | 18.1 |

38 | 19*19 | 1007*4007 | 40 | 23.5 |

The grating installation guidance.

1. Tool selection: FRP grating can be cut by ways of a ceramic disc or emery disc cutter to cut into the desired size. Generally, when ordering, we can cut it according to the size given by the customer.

2.Fixing of tools: When cutting with a heavy-duty cutting machine, it should be fixed to prevent the grating and cutting machine from moving.

3. Safety protection: Before cutting, the operator should wear protective eyes, masks, gloves and work clothes, and choose a well-ventilated, bright place.

4. Size check: Please consider the width of the blade saw mark before cutting, the length and width deviation of the grille after cutting is -6mm~0mm; the circular diameter size deviation is -9.5mm~0mm;

Installation accessories

Packing Details

Q1. What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3. Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4. Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

5. How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6. what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Hot Tags: fiberglass covered grating, China, manufacturers, factory, price, Fiberglass pultruded mould, FRP L Angles, fiberglass telescopic bird pole, SMC BMC Mold, fiberglass roof panel, FRP slat floor