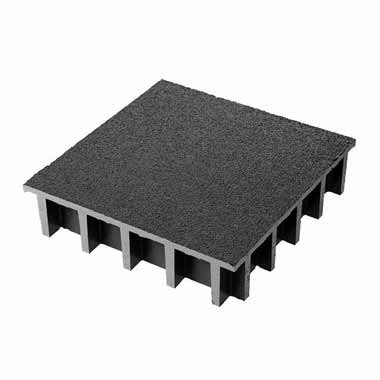

FRP purlins are generally used to build roofs. Common specifications are: 160*55*5 rectangular tube, 160*55*5 day tube, 180*100*10 rectangular tube, 220*55*5 day tube. The length can be cut arbitrarily.

The purlin made of glass fiber reinforced plastic is mainly considered for its high strength and corrosion resistance. For example: 160*55*5 day-shaped tube after 10 hours of continuous bearing pressure of 800Kg, the profile returns to its original shape, and the resilience of the glass fiber reinforced plastic purlin is considered to be a good material for earthquake resistance and typhoon resistance.

characteristic:

1. The axial strength of FRP purlin material reaches 290Mpa, which has reached the strength of steel.

2. With its high strength, corrosion resistance and good aging resistance, there is no other material that can replace its cost performance.

The anti-corrosion purlin is made of unsaturated polyester resin, alkali-free glass fiber yarn and processing aids as the main raw materials, using special formulas and processing through scientific production processes. The anti-corrosion purlin has reasonable design and special raw materials, so that the product has the strength of steel, and fundamentally solves the weak point of metal steel that is easy to corrode.