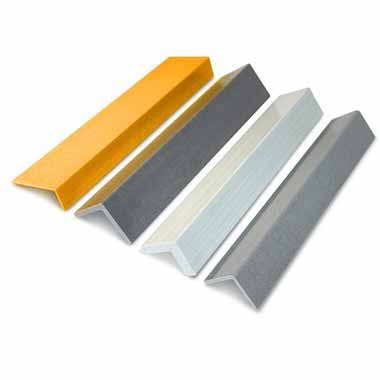

FRP purlins have excellent electrical insulation, no electromagnetism and electric sparks, and can be used in areas where there is a risk of electrical conduction, magnetic equipment, and flammable places. FRP purlin is a kind of thermal insulation material with a much lower coefficient of thermal expansion than ordinary plastics. Pultrusion has excellent mechanical properties at low temperatures and will not melt at high temperatures, but its strength and modulus will be reduced to a certain extent at high temperatures. Generally, the applicable temperature range of pultruded profiles is -50℃-100℃!

FRP purlin is a product made by machine pultrusion through glass fiber. FRP pultruded profiles generally include FRP railings, FRP round tubes, FRP square tubes, and other FRP products. The general shape can be designed according to customer requirements. The glass fiber reinforced plastic purlin also has certain requirements on the process. Such as: traction speed, traction force, immersion time, etc. The pultrusion speed is generally between 250-500mm/min. The specific speed mainly depends on the performance of the resin glue liquid initiating curing system. Faster resin curing means faster pulling speed; otherwise, the pulling speed is slower. Under the condition of a certain mold temperature, the solidified gel area of the general profile should be determined at 150-200mm from the entrance of the mold. This can prevent the surface of the product from cracking due to overheating of the product when the product is cured and exothermic. The impregnation time of the reinforcing material is based on the impregnated surface felt and the untwisted roving, and each batch of raw materials is based on the test. The immersion time of ordinary reinforcing materials is 60-120s.